How to correctly install UPVC/CPVC Reducer Bushing? Key steps and common mistakes to avoid

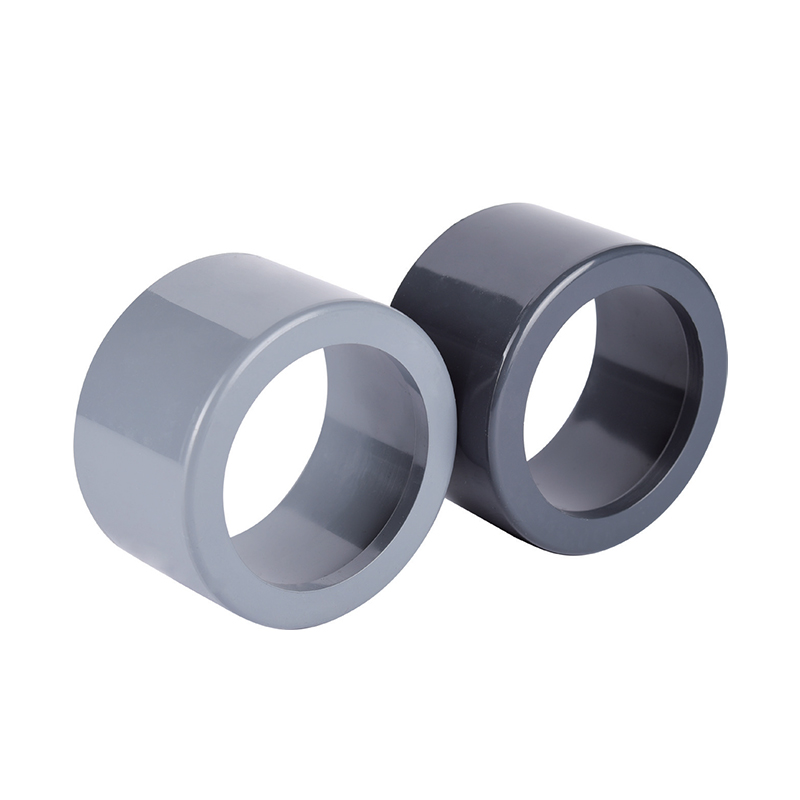

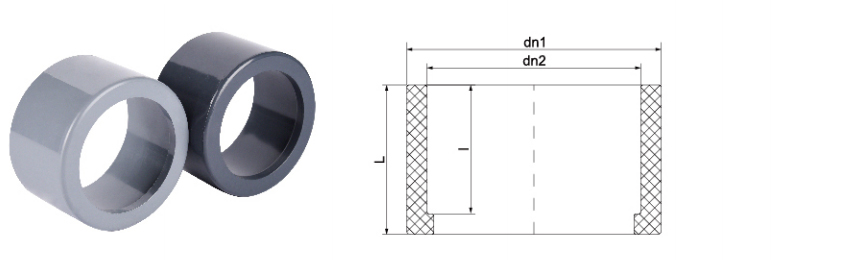

UPVC (unplasticized polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride) reducer bushings are widely used in pipeline systems in different industries, such as safe drinking water, metallurgy, photovoltaic, nuclear power, electronic semiconductor, medicine, industrial water treatment and industrial wastewater. Correct installation can ensure long-term stable operation of the system and avoid leakage and material failure. The following are key steps and common mistakes:

Key installation steps

1. Material inspection and matching

Confirm the material: UPVC is suitable for normal temperature (0°C~60°C) and corrosive environment, such as industrial wastewater treatment; CPVC is resistant to high temperature (up to 93°C), suitable for high temperature scenes such as photovoltaic cooling system and nuclear power auxiliary pipeline.

Check the size: Make sure the bushing matches the pipe size to avoid installation difficulties or poor sealing due to size errors.

2. Pipe cutting and deburring

Use special cutting tools (such as PVC cutters) to ensure smooth cuts and avoid jagged edges that affect sealing.

Use sandpaper or deburring tools to clean the cuts to prevent residual debris from entering the high-purity water system of the pharmaceutical or electronic semiconductor industry.

3. Cleaning and solvent preparation

Use UPVC/CPVC special cleaner to remove oil and dust from the contact surface of the pipe and the bushing (especially in the metallurgical and industrial water treatment industries, impurities may cause corrosion or blockage).

Use matching CPVC adhesive (high temperature resistant) or UPVC adhesive to avoid mixing and causing bonding failure.

4. Gluing and installation

Evenly apply adhesive to the outer wall of the pipe and the inner wall of the bushing, quickly insert and rotate 1/4 turn to ensure even distribution of glue (suitable for high sealing requirements of nuclear power and drinking water systems).

Maintain pressure for 10-15 seconds to avoid loosening.

5. Curing and testing

Wait for curing according to the ambient temperature (usually 2 hours for UPVC and 4 hours for CPVC). The curing time needs to be extended in clean pipes in the electronic semiconductor or pharmaceutical industries.

Perform pressure testing (water pressure or air tightness testing) to ensure that there are no leaks, especially in industrial wastewater or high-temperature photovoltaic coolant systems.

Common mistakes and avoidance methods

Error 1: Failure to distinguish between UPVC and CPVC materials

Consequences: Using UPVC cores at high temperatures (such as nuclear power or metallurgical cooling systems) may cause deformation or rupture.

Solution: Select materials strictly according to the medium temperature. CPVC is suitable for environments ≥60°C.

Error 2: Improper use of adhesives

Consequences: Using ordinary PVC adhesive to bond CPVC leads to insufficient temperature resistance (such as easy failure in photovoltaic cooling circulation systems).

Solution: CPVC special adhesive must be used and ensure that it is within the validity period.

Error 3: Failure to thoroughly clean or deburr

Consequences: Impurities enter the pharmaceutical or electronic semiconductor ultrapure water pipeline and contaminate the medium.

Solution: Wipe with a dust-free cloth before installation and check the smoothness of the cut.

Error 4: Insufficient curing time

Consequence: Early water flow/pressure test causes core debonding (common in emergency repair scenarios of industrial water treatment).

Solution: Strictly wait for curing according to the instructions of the adhesive. High temperature and high humidity environment prolongs the waiting time.

Error 5: Ignoring system compatibility

Consequence: Use non-corrosion-resistant cores in acidic industrial wastewater, or directly connect to metal pipes without insulating gaskets (electrochemical corrosion).

Solution: Confirm the chemical compatibility of the medium and use transition joints when necessary.

Industry application precautions

Drinking water: NSF-certified UPVC/CPVC materials must be used to avoid toxic substances from precipitating.

Nuclear power: Select radiation-resistant CPVC and pass the seismic test.

Electronic semiconductor: The installation environment must be dust-free to avoid particle contamination of the ultrapure water system.

+86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com